YOUR CART IS EMPTY

FAST SHIPPING & KNOWLEDGEABLE CUSTOMER SERVICE

SPEAK TO A MEDICAL GAS SPECIALIST 954-725-1470 | Order History

All tests are conducted by ASSE 6040 Hospital Maintenance Personnel, and ASSE 6030 Verifiers.

All medical gas outlets / inlets will be tested for correct pressure/vacuum readings, flow rates, and particulate matter, leaks, cross connections, pressure drop, and labeling / proper coloring.

BA&C gauge pressures will be compared to line pressure gauges on the zone valves for accuracy and correct labeling will be noted. The final report will list each zone valve in the facility and the area(s) served. BA&C will test medical gas valves and zone valves for leakage using an ultrasonic leak detector.

BA&C gauge pressures will be compared to line pressure alarm gauges on the area alarm panels. Area alarms will be checked and/or tested for all audible and visual signals, high alarm set point, low alarm set point (if available), and correct operating pressures. As per the TJC requirement BA&C will functionally test the sensors for each area alarm (where possible without interrupting gas flow) utilizing the BA&C Area Alarm testing device. The final report will list each area alarm in the facility and the area(s) served; if area alarms are not labeled as to the area served it will be so noted on the final report.

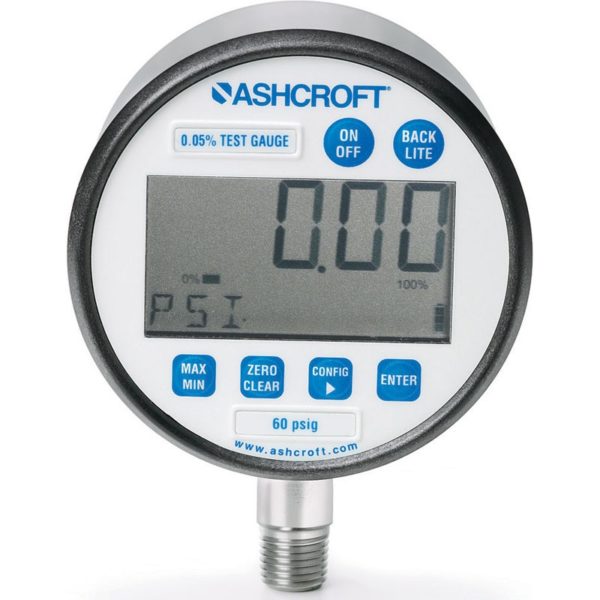

Master alarm testing will be performed where available and where the facility staff and configuration allow it. As per the TJC requirement BA&C will functionally test all pressure switches, lag alarms, dew point, and co alarms, and related manifold / bulk gas alarms. Pressure switches will be tested with an BA&C Master Alarm Testing Device (pictured above). Alarm set points will be adjusted where possible and where needed. Master alarm will be checked and/or tested for all audible and visual signals. BA&C will not disrupt the gas supply in any way during the testing.

Manifolds will be tested for proper alarm functions, bank switchover capability and alternating sequence (if available), correct gauge indication (not calibration), gas leakage, and relief valve operation. Written reports will reflect location, correct manifold operation, and labeling.

Source equipment systems will be checked for code compliance as per NFPA 99, proper suction or pressure delivery, automatic and/or manual alternation, proper voltage, proper amperage draw, oil levels, filter conditions, and unit hours. All valves, intakes / exhausts lines, and pressure switches shall be checked for leakage and proper operation where available.

Broward A&C Medical Supply, Inc. produces a comprehensive report with deficiencies and recommended corrections in a timely manner. We can review the report with you and/or staff to ensure you stay in compliance.

Corporate Address:

1533 SW 1st Way, Suite F19

Deerfield Beach, FL 33441

Office: 954-725-1470

Email for Medical Gas: [email protected] Email for Parts: [email protected]

Hours of Operation

Monday – Friday

8 AM to 4:30 PM